Kishigo vs. the Competition: Unmatched Quality in Hi-Vis Workwear

Kishigo vs. the Competition: Unmatched Quality in Hi-Vis Workwear

You don’t buy safety apparel for the label, you buy it to protect people. But here’s the problem: many high-visibility vests and jackets look the same on the surface. Until they don’t. Weak stitching. Cheap closures. Fabrics that fade fast or trap heat.

That’s where Kishigo stands apart. Our workwear is built to outlast and outperform the alternatives. It’s not just a claim; many of our customers become repeat buyers after seeing the difference for themselves. In this guide, we’ll walk through how our quality stacks up against standard options on the market, and why that matters to your team and bottom line.

Quality: Built to Last vs. Built to Sell

Meeting ANSI standards is the starting point, not the finish line. Workers need gear that not only passes inspection but also holds up to the demands of the job. Here’s where the differences in quality start to show.

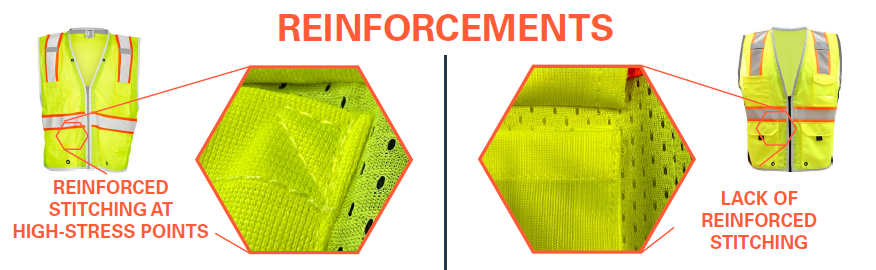

Reinforced Stitching

Kishigo: Every vest, shirt, and jacket is reinforced at key stress points. We add reinforcements at zippers and pockets, so garments don’t fall apart after a few tough shifts. This durable sewing construction helps prevent rips, snags, and seam blowouts, making each piece more durable over time.

You’ll find this kind of reinforcement in workwear that’s meant for serious daily use. We know that crews aren’t just walking around, they're bending, lifting, carrying, climbing, and constantly moving. Their high-vis isn’t just clothing, it’s a tool they rely on. That’s why our reinforcements are built to handle the wear that comes from hard work, not just casual wear.

The Alternative: Some common alternatives skip this step entirely. It’s a cost-cutting move that makes a difference. When key stress points aren’t reinforced, wear and tear shows up fast, especially in demanding work environments. That leads to quicker breakdowns and more time spent replacing what should have lasted.

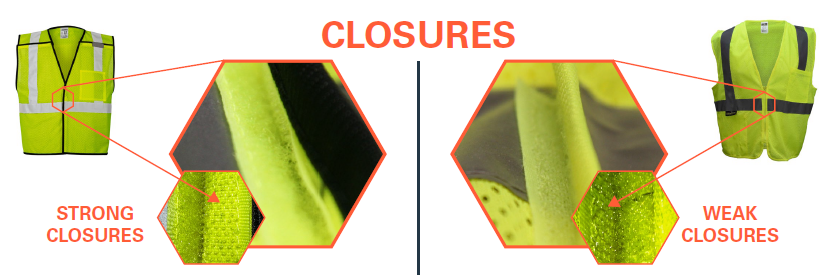

Closure Systems

Kishigo: We use high-density hook-and-loop closures engineered for repeat use. Our closures grip firmly, stay put, and hold their shape after hundreds of wears.

Closures get more action than almost any other part of a vest or jacket. They’re tugged, adjusted, and re-fastened constantly. That’s why we invest in closures that actually hold up. Ours don’t peel open halfway through a shift or lose grip after a few washes.

The Alternative: Some brands use thinner hooks with fewer loops per square inch. The result? Weak closures that detach throughout the day, get clogged with debris, or stop sticking altogether. That’s not just annoying, it’s a hazard.

You’ll often find closures on budget vests that feel soft or flimsy from day one. After a few days on-site, they start curling, popping open, or gumming up with dirt. That might seem like a small issue until it compromises how the vest fits, or whether it stays on at all.

Fabric Quality

Kishigo: We select materials designed for repeated washing, outdoor exposure, and heavy use. Our fabrics maintain brightness and structure, shift after shift.

Every fabric we use goes through a selection process focused on long-term wearability. This means resistance to fading under sunlight, stability through industrial laundering, and durability against sharp tools, abrasive surfaces, and high-friction areas like shoulders and waistlines.

The Alternative: Cost-saving fabrics fade faster, shrink in the wash, or lose reflectivity. What starts out ANSI-compliant may no longer meet standards after a few weeks in the field.

We’ve seen vests go from bright to dull after just a handful of washes, especially when exposed to direct sun or jobsite grime. Faded or distorted fabric not only looks worn out, it puts workers at risk when visibility is reduced in critical conditions like low light, dust, or traffic-heavy zones.

Read More: Is Your Hi-Vis Workwear Putting You at Risk? Here's When to Replace It.

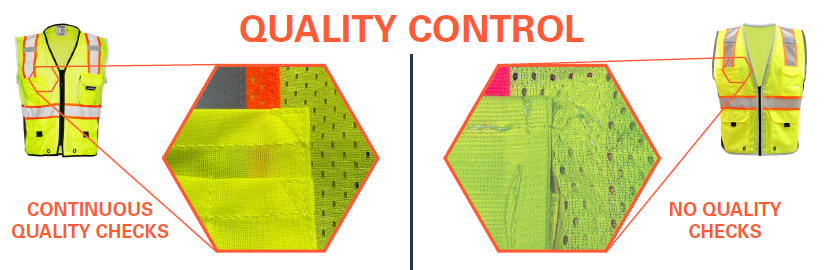

Quality Control

Kishigo: We inspect every garment throughout the production process, not just at the end. That means our inventory meets a consistent standard from batch to batch. No loose threads. No uneven stitching. No surprises. It’s how we make sure what shows up on your jobsite reflects the brand behind it.

Whether it's a vest, jacket, or shirt, our quality assurance steps are there to catch issues before they reach the field. This is how we build reliability into every shipment, not just into the garment itself.

The Alternative: Without checks at key points in the process, flaws slip through. That’s how you end up with pockets that unravel, seams that don’t hold, and inconsistent sizing. These aren’t just cosmetic issues, they lead to returns, worker complaints, and gear that doesn’t hold up under pressure.

When the gear works the way it should, crews can focus on the job, not the vest on their back. That’s where the right choice really pays off.

Download Now: The Economic Benefits of Investing in High-Quality Safety Apparel.

Choose Workwear That Works as Hard as You Do

At Kishigo, we’ve spent over 50 years building apparel that puts safety, comfort, and durability first. We don’t cut corners. We don’t compromise on materials, and we don’t believe in gear that just looks good in a catalog.

If you’re tired of replacing vests that don’t hold up or managing crews frustrated by what they’re wearing, it might be time to make a switch. Kishigo products are built to last, delivering more wear, fewer replacements, and a stronger return on your PPE investment.

Compare for yourself. Try Kishigo, and see what quality feels like.